Introduction

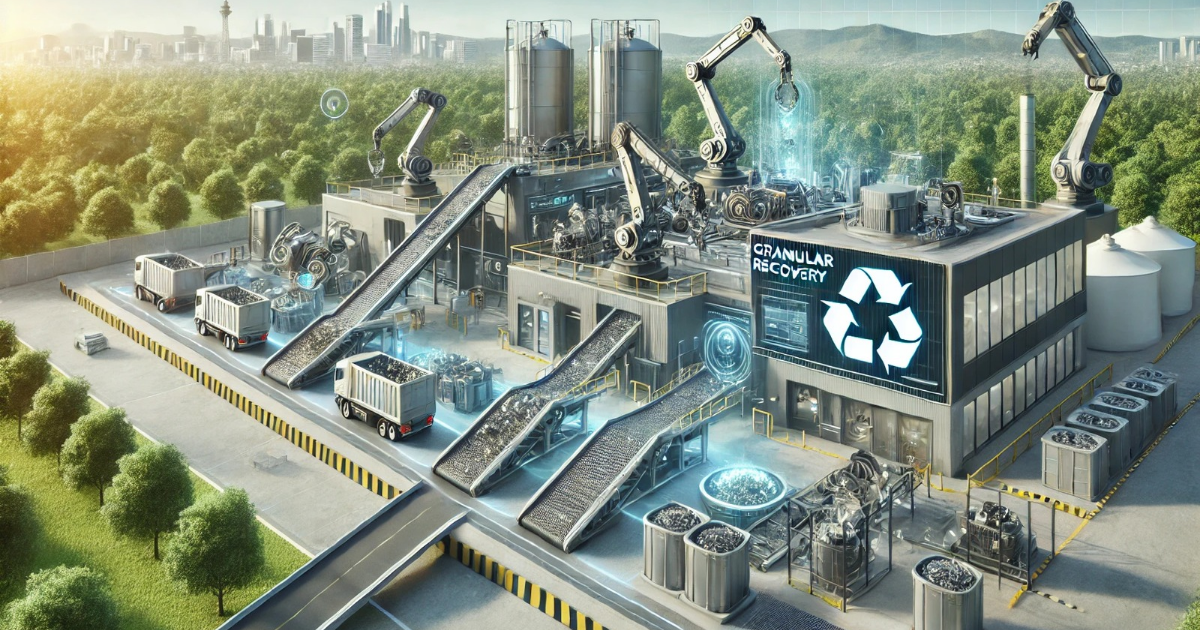

In an era where sustainable waste management is crucial, Granular Recovery Technology (GRT) has emerged as a game-changer. Industries across the globe are seeking innovative ways to recover valuable materials from waste streams efficiently. GRT offers a sustainable and cost-effective solution by enabling the separation and extraction of granular materials, which can be reused or repurposed, reducing environmental impact and economic losses.

This article delves deep into Granular Recovery Technology, explaining its working principles, benefits, applications, and future prospects.

What is Granular Recovery Technology?

Granular Recovery Technology is an advanced method used to extract and recover granular materials from various waste sources. These granules can be composed of metals, plastics, minerals, and organic compounds, making GRT a versatile approach applicable in multiple industries.

The primary goal of GRT is to minimize waste by recovering reusable and recyclable materials efficiently. This technology relies on mechanical, chemical, and thermal processes to segregate and purify granules from waste streams.

How Does Granular Recovery Technology Work?

GRT involves several systematic processes that ensure maximum recovery of granular materials. Here’s a breakdown of its working mechanism:

1. Material Collection & Sorting

- The process starts with the collection of waste materials from industrial, municipal, and commercial sources.

- Advanced sorting techniques like optical sensors, density separation, and magnetic fields help segregate granular components efficiently.

2. Granule Identification & Classification

- Sophisticated AI-driven sorting systems analyze the composition of granules.

- Materials are classified based on size, density, and chemical properties to ensure effective processing.

3. Separation Techniques

- Magnetic Separation: Used for ferrous and non-ferrous metal recovery.

- Electrostatic Separation: Helps in recovering fine metal particles from non-metallic components.

- Density-Based Separation: Enables the separation of materials based on weight differences.

- Chemical Extraction: Involves the use of solvents or reagents to extract valuable compounds.

4. Processing & Refinement

- Recovered granules undergo refining, melting, or chemical treatment to enhance purity.

- The refined materials are then processed into reusable raw materials for various industries.

5. Final Product Utilization

- The extracted granules are supplied to industries such as construction, manufacturing, electronics, and automotive sectors.

- Some granules can also be reused in 3D printing, agriculture, and energy production.

Key Benefits of Granular Recovery Technology

The adoption of Granular Recovery Technology offers a multitude of benefits, both environmentally and economically:

1. Reduces Environmental Impact

- Prevents valuable materials from ending up in landfills.

- Reduces carbon footprint by minimizing the need for new raw material extraction.

2. Enhances Resource Efficiency

- Maximizes recovery and reuse of valuable granules, leading to less resource depletion.

- Encourages the circular economy by promoting sustainable material use.

3. Cost-Effective Solution for Industries

- Reduces waste disposal costs by recovering reusable materials.

- Generates additional revenue by selling recovered materials to manufacturing units.

4. Supports Sustainable Development Goals (SDGs)

- Contributes to responsible consumption and production (SDG 12).

- Promotes clean industry innovations (SDG 9).

5. Minimizes Dependence on Mining & Extraction

- Reduces the demand for virgin materials, lowering the environmental and social impact of mining activities.

- Lessens water and energy consumption in raw material processing.

Applications of Granular Recovery Technology

GRT has applications in various industries, making it a highly sought-after technology. Below are some of its most impactful uses:

1. Waste Electronics & E-Waste Recycling

- Extracts gold, silver, copper, and rare-earth metals from discarded electronic devices.

- Reduces toxic waste accumulation from outdated electronic products.

2. Construction & Demolition Waste Management

- Recovers concrete granules, metal scraps, and plastic materials for reuse in construction projects.

- Lowers construction costs by utilizing recycled materials.

3. Plastic Waste Recovery

- Separates different types of plastics for recycling and reprocessing.

- Converts plastic granules into new packaging materials or synthetic textiles.

4. Mining & Mineral Processing

- Extracts valuable minerals and ores from mining waste.

- Reduces the environmental burden of traditional mining methods.

5. Food & Agricultural Waste Utilization

- Extracts organic compounds for fertilizers and biofuel production.

- Converts agricultural by-products into value-added materials.

6. Textile & Fiber Recovery

- Segregates synthetic and natural fibers for repurposing into new fabric products.

- Reduces the environmental impact of fast fashion waste.

Challenges in Implementing Granular Recovery Technology

While GRT offers significant advantages, certain challenges must be addressed for widespread adoption:

1. High Initial Investment Costs

- Advanced sorting and recovery systems require substantial capital investment.

- Smaller businesses may struggle to afford cutting-edge recovery solutions.

2. Technical Complexities in Material Separation

- Some materials have similar physical and chemical properties, making separation difficult.

- Requires continuous R&D efforts to enhance sorting accuracy.

3. Lack of Standardization

- The absence of universal guidelines for granular recovery hinders efficiency.

- Industry-wide standards are needed for uniform quality control.

4. Public Awareness & Policy Support

- Limited awareness about GRT benefits slows down adoption.

- Stronger government regulations and incentives can drive faster implementation.

The Future of Granular Recovery Technology

With growing environmental concerns and stricter waste regulations, the future of Granular Recovery Technology looks promising. Several trends are shaping the next phase of GRT:

1. Integration of Artificial Intelligence & Machine Learning

- AI-powered sorting algorithms improve material classification and separation.

- Machine learning helps optimize granule recovery efficiency over time.

2. Expansion of Circular Economy Initiatives

- More industries are investing in closed-loop recycling systems to minimize waste.

- Increased collaboration between manufacturers, recyclers, and policymakers to enhance recovery rates.

3. Advancements in Bio-Based Recovery Solutions

- Enzymatic and microbial processes are being explored for organic material recovery.

- Bio-friendly solvents may replace hazardous chemicals in extraction processes.

4. Growth in Sustainable Manufacturing Practices

- More companies are adopting eco-friendly material sourcing and production methods.

- Governments are offering incentives for businesses using recovered granular materials.

5. Global Waste Management Policies Supporting GRT

- Stricter waste disposal laws and recycling targets encourage GRT adoption.

- International collaborations may lead to standardized recovery techniques worldwide.

Conclusion

Granular Recovery Technology is revolutionizing the waste management sector by transforming discarded materials into valuable resources. By leveraging advanced sorting, extraction, and processing techniques, GRT plays a crucial role in achieving sustainable waste solutions and promoting a circular economy.

Despite challenges like high costs and technical limitations, the continuous evolution of technology is making GRT more accessible and efficient. Industries worldwide are increasingly recognizing its potential, making Granular Recovery Technology a vital pillar of modern waste management strategies.

With ongoing advancements, policy support, and increased awareness, GRT is set to play a pivotal role in the global transition towards sustainable resource recovery and environmental preservation.